How to operate the garbage spray deodorizer?

In densely populated big cities, the treatment of waste deodorants is a headache inducing problem. The common approach is to collect and send them to landfill areas for landfill treatment, or use incinerators for incineration. But both will create environmental protection issues, and ending excessive consumption can further reduce the saturation level of landfills. It involves the collection, compression, transportation, and odor purification of waste at waste stations.

The main principle of the waste deodorization system is to use efficient bacterial strains to treat toxic odorous organic waste gases containing hydrogen sulfide, ammonia, mercaptan, sulfide, benzene, toluene, chlorobenzene, low fatty hydrocarbons, alcohols, aldehydes, ketones, and other evaporative organic compounds in a biofilter. The core technology of microbial breeding, biofilm development, is beneficial for packaging and microbial strains that facilitate biological adhesion and growth. Microorganisms use inorganic and organic waste gases as carbon and energy sources in a suitable environment under biological filtration conditions. After degradation by foul smelling substances, they maintain their living and reproductive activities, and differentiate foul smelling substances into water, carbon dioxide, and odorless substances, achieving the goal of purifying foul smelling gases.

The process of deodorization treatment for odor pollutants and biological waste in the era

Microbial biochemistry and biological deodorization use differentiation pollutants to produce or reduce pollutants. Microorganisms use organic compounds as substrates for growth, and through different transformation methods, they differentiate large or complex structures of organic matter that undergo differentiation and final oxidation into simple inorganic substances such as water and carbon dioxide. The energy generated during the process of assimilation and differentiation together promotes the growth and reproduction of microbial organisms, in order to further develop their ability to invent organic substances with favorable conditions.

The essence of pollutant removal is that organic substrates are absorbed, metabolized, and utilized by microorganisms as nutrients. This process is relatively complex and includes physics, chemistry, physics, chemistry, and biochemistry.

Odorous substances dissolve in water and are then absorbed by microorganisms, which differentiate and utilize nutrients to remove pollutants.

When using biofilm to purify odors, the process is different from pure physical absorption due to organic pollutants and biochemical reactions. The purification of gas by biofilm method can be divided into three steps.

Dissolution process of foul odor gas

The exhaust gas comes into contact with water or the solid phase on the surface of the water film, and the molecules or ions of pollutants in the water are in the liquid phase. In other words, the transfer of odorous substances from the gas phase to the liquid phase is a physical process that follows Henry's law: Pi =HXi type π - soluble gas at equilibrium partial pressure in the gas phase, MPaH - Henry's coefficient, MPa Xi, soluble gas in liquid phase mole fraction.

Microbial Skills For deodorization of waste sites, special deodorization products of waste sites are used, complex biological active agents made of microorganisms, biological enzymes and nutrients, and cooperative mobile high-pressure spray deodorization system equipment, which can effectively control the evaporation of undesirable gases.

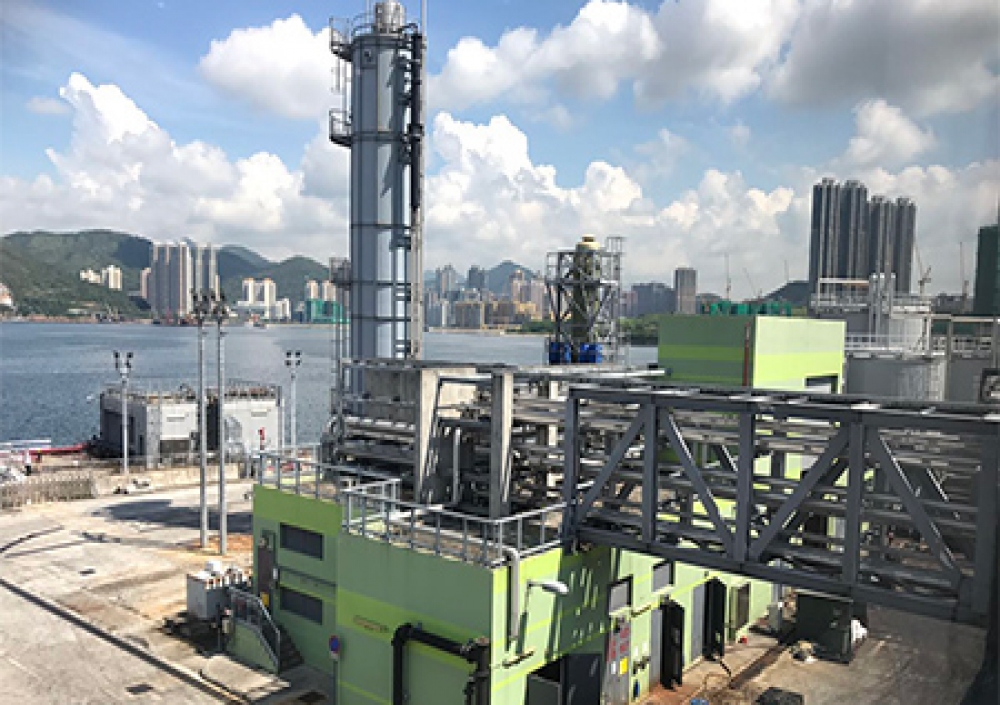

Strong microorganisms and active enzymes use inorganic and organic substances in exhaust gas as carbon sources and power, which will significantly degrade odorous substances in the process of maintaining life activities, and differentiate odorous substances into odorless substances such as water and carbon dioxide. The mobile high-pressure spray deodorization system adopts the combination of automatic control and manual control, which has obvious effect of deodorization and dust reduction. The traditional method of odor collection and centralized treatment is changed to local differentiation and purification treatment, greatly improving the working conditions of waste treatment sites, and together dealing with the surrounding atmospheric environmental pollution.

Biological deodorization skills and products have been widely applied in urban sewage treatment plants, waste treatment plants, industrial high concentration organic wastewater, eutrophication water correction of natural rivers and lakes, waste from aquaculture farms, wastewater treatment, aquaculture, as well as deodorization in households and public places.

The deodorization process of waste disposal sites has always been a necessary process for various waste transfer stations, landfills and other areas. The deodorization products of waste disposal sites are widely applicable to deodorization of various waste transfer stations and landfills. According to different places and odor sources, corresponding deodorization processes can be planned to remove odors and purify the environmental air.

Biological deodorization of waste landfill areas

The odor in the house can be covered by spraying perfume, but the amount of perfume used in such a large landfill can not cover the odor. In view of the pollution situation in different areas of the waste landfill, the expert group has formulated the "Integrated Management Plan for Odor in Laohuchong Waste Landfill", which will adopt the combination of three methods of masking, biological deodorization, and centralized treatment of plant liquid to manage the odor.

Implement sealing and covering treatment in non work areas, extract landfill gas for incineration and power generation. Use spatial biological deodorization methods to treat the landfill operation area. Fully seal and cover up the leachate sewage pit, and extract and incinerate the foul odor gas. The leachate conditioning tank is managed using a plant liquid collection and treatment process.

The article originates from a deodorant manufacturer http://www.scneng.com.hk

-

06-11

"Environmental Doctor" Du Siyuan: Environmental Protection is a Lifestyle Attitude

There is a Hong Kong compatriot in Jiangmen who often frequents various farms and plantations, walks in mechanical factories, and is seen by others as the nemesis of environmental problems. He conside

-

03-16

Deodorant manufacturer: Deodorants reduce soil pollution

Waste is a chaotic mixture of various components. The accumulation of debris on the surface of soil can cause some chemical reactions, releasing harmful gases, which can lead to soil pollution and eve

-

12-01

Deodorant Manufacturers: Differences between Microbial Deodorants and Traditional Deodorants

The waste that is not needed in our daily life and work is called waste. Due to the large amount of waste discharged and the complex categories, there are great difficulties in reducing waste and deod

-

11-08

Application of Deodorant Manufacturers in Domestic Waste Treatment

Garbage is the waste generated in everyone's daily life and work. Due to its large discharge volume and complex and diverse composition, it poses great difficulties in reducing and deodorizing wa